Most lamps can be used to fuel photosynthesis, assuming they are bright enough. And almost every type of lamp has been used for the purpose. The problem with most is that a lot of energy is wasted if the source of light does not emit the optimal color combinations for plant growth.

The most popular light for horticultural use is a high-intensity discharge (HID) light and specifically, the high-pressure sodium (HPS) bulb. Today, LED lights are gaining in popularity and will most likely overtake HPS lighting in the near future.

The reason for this is simple: due to their customizability, LED lighting solutions make for more efficient grow lights than high-pressure sodium lamps. Note that this is only true of LED grow lights that have been optimized with the ideal bandwidths of light for plant production, like the Black Dog series of lights. Cheap lights do not generally provide the perfect spectra in the perfect ratios and are thus much less efficient.

Introduction

Choosing the ideal light source is one of the most important decisions for horticultural operations. Natural sunlight is best for field crops growing in their native area, but non-native plants growing in greenhouses or other artificial grow spaces like grow tents, etc., require artificial lights.

Every type of lamp has advantages and disadvantages, but we will look at only the two most popular. High-pressure Sodium (HPS) lamps and Light-Emitting Diode (LED) lamps share many of the same advantages, like energy efficiency and a low cost per lumen. However, LED lamps have several additional advantages over HPS lamps.

HPS Bulbs Provide Less Usable Light

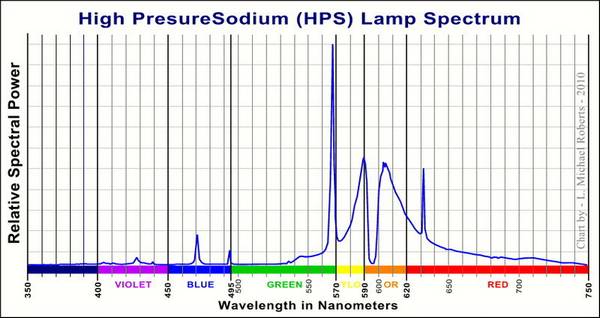

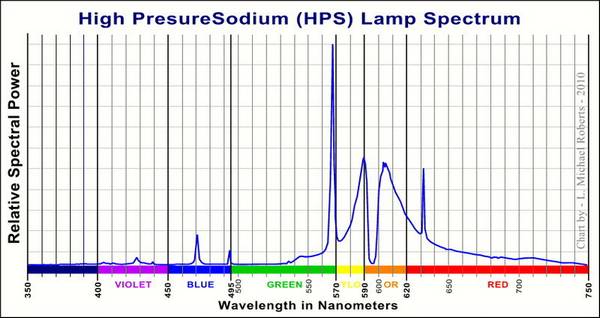

HPS light produce a spectrum heavy in the green and yellow regions, with lower quantities of light in the orange-red region and almost none in the blue-violet ranges. This is illustrated in the graph below.

Most plants use only a small amount of green and yellow light for photosynthesis. As a result, more total light—and with it more energy—is needed to give plants sufficient light in the spectra they do use. All of the energy used to provide the green and yellow light is thus wasted.

In contrast, LED horticulture lights can be customized with LED diodes in any combination of colors. As a result, most manufacturers outfit their lights with mostly blue and red diodes and usually only a few white ones (white diodes give off all spectra, including yellow and green). No energy is wasted and plants get exactly what they need for optimal growth and yield.

HPS Grow Light Bulbs Emit Unhealthy Light For Plants

All sodium lamps produce visible light in the yellow range. They also give off infrared radiation, which comes in the form of heat. We can't see this light, but we can certainly feel it (and so can plants).

High-pressure sodium lamps do produce some additional light that is outside of the yellow range, which is why they can be used to grow plants (low-pressure sodium lamps usually produce yellow light only, with no other colors).

The strong yellow light does little to fuel photosynthesis and the extreme heat can exert considerable stress on your plants. This is why growers have to hang HPS fixtures high above their plants—it keeps the lights from causing damage.

HPS Lights Are Far From Optimized For Plants' Needs

High-pressure sodium light is optimized for visible light output. It is some of the best light out there for lighting up an area at a low cost. It is especially good as directional lighting, i.e., situations where contrast is required, but the color of the light doesn't matter. Good examples of this are streetlights used to light up roadways or sidewalks.

HPS lights are perfect for use in streetlights near an observatory or a similar installation that could be harmed by light pollution. Unlike blue light, yellow light does not travel very far, and since HPS light contains almost no blue wavelengths, its light does not leave the area where it is needed. In other words, it does not extend far up into the sky where it could impede a nearby observatory. (Harder, 2007)

This very same lack of blue light that cuts down on light pollution makes the HPS lamp less useful for photosynthesis. Much of the light energy in the heavily yellow-weighted spectrum of the HPS is wasted. The use of HPS for horticulture is a compromise, using a light source that was never designed specifically for photosynthesis. Note that blue light is more harmful to our eyes, though, so you may want to consider getting some protection.

High Heat Production Can Damage Plants

All sources of light produce both light and heat. The more heat produced, the more energy required to produce a certain amount of light. And the more heat produce, the more energy required to keep the grow space cool.

Another problem of high heat production is damage to plants. Light fixtures that produce much excess heat must be kept far away from delicate plant tissues to prevent burn damage. This means fixtures that run hot, like HPS lights, must be placed far above the plant canopy. Doing so requires a taller grow space, which further increases costs.

HPS lamps produce far more heat than LED lamps when they are both putting out the same amount of light. With their lower heat production, LED lamps are unlikely to cause leaf-burn. This presents an added bonus: it is possible to safely place LED lamps beneath the leaves of plants.

A study on the optimum lighting for leaves, conducted by Dale N. Moss with support from NASA and the Connecticut Agricultural Experiment Station, showed that exposing the chloroplasts on both the upper and the lower surfaces of leaves to light will result in maximum photosynthetic productivity (Moss, c. 1963). LED lamps can be used to light leaves from the bottom; due to their high heat production, HPS lamps cannot.

LED Lights Provide Only The Specific Wavelengths Required For Photosynthesis

When it comes to plant lighting, LED grow lights have a large advantage over other light sources: the fixtures can be optimized to provide any desired ratio of colors.

Any color of light can be produced by combining two techniques: using different materials to construct the semiconductor (the component that actually emits the light) and using different color filters on the casing around the semiconductor (the actual bulb part of the diode). By altering the material used in the semiconductor and/or the color of the filter, you can produce virtually any color of light, including non-visible light, like infrared and ultraviolet.

High-quality horticultural LED lamps include combinations of diodes in various colors, in a ratio optimized for the type of plant being grown. For most plants, this means a combination of reds and blues (some grass crops, only need red light). (Tikhomirov, A.A.,1994; Bugbee, B.,1994)

Conclusion—HPS is Good, LED is Better

Virtually any type of artificial light has, at some point, been used for horticultural purposes. Since greenhouse operators and the space agencies both share an interest in determining which light sources produce the best results while consuming the fewest resources in terms of energy (to run the light and to cool the grow area) and grow space and cooling, a large number of studies have been, and will be, conducted to determine which artificial light sources are the most effective and efficient.

Since high-pressure sodium lights produce an intense light at a relatively low cost, they are widely used in horticulture. However, they do not emit the ideal combination of colors and also produce a large amount of heat. As a result, more energy is needed to run the lights and even more to cool the growing area. Furthermore, the lights must be kept far from the canopy to prevent leaf burn.

LED grow lights, on the other hand, require less electricity to run and, due to their lower production of excess heat, less electricity to keep down the temperature of the grow space. The lower heat also means no burn damage to plants—in many cases, even when there is extended leaf-on-bulb contact. Finally, LED fixtures can be customized with the optimal ratio of colors for plant growth. All of this means you get better growth and higher yields at a much lower cost.

Finally, I just want to add that there are some key differences you need to be aware of when growing with LEDs. Most first-time LED growers are not aware of them, and they end up with very disappointing results. You can read about the differences and what to do about them here.

Now it's your turn

Which do you prefer, HPS or LED? Or a different type of grow light altogether?

Let us know in the comments below!

Have you decided on LED, but aren't sure which one is best for you? Check out our popular free LED buying guide! (Prefer HID? We have one for HID lights as well.

References

Moss, D.N. (c1963).Optimum Lighting of Leaves. Connecticut Agricultural Experiment Station with financial support from NASA, unpublished preliminary data, N63 16152.

Roberts, L.M. (2010). Spectrum of a typical High Pressure Sodium (HPS) lamp. High_Pressure_Sodium_Lamp_Spectrum.jpg.LMRoberts at en.wikipedia.

Bugbee, B. (1994). Effects of Radiation Quality, Intensity, and Duration on Photosynthesis and Growth.In T.W. Tippets (Ed.).NASA-CP-95-3309, International Lighting in Controlled Environments Workshop, Kennedy Space Center, FL: National Aeronautics and Space Administration.

Harder, S. (2007). White Paper: Metal Halide (MH) vs High Pressure Sodium (HPS). Paper concerns outdoor lighting such as street lamps. Accessed online at www.darkskysociety.org/handouts/white_paper--mh_vs_hps.pdf

Campbell, T. (2012).White Paper: The Right Lighting for Photosynthesis: Which Wavelengths are Most Important and Why? Prepared by the author for Blu LED.

Buil, C (undated). Spectral Calibration.On Spectroscopy, CCD & Astronomy.

Tikhomirov, A.A. (1994). Spectral Composition of Light and Growing of Plants in Controlled Environments.In T.W. Tippets (Ed.).NASA-CP-95-3309, International Lighting in Controlled Environments Workshop, Kennedy Space Center, FL: National Aeronautics and Space Administration.

Geiger, D.R. (1994). General Lighting Requirements for Photosynthesis. InTibbits, T.W., International Lighting in Controlled Environments Workshop, National Aeronautics and Space Administration, John F. Kennedy Space Center, Kennedy Space Center, Florida.

Comments

Leave a comment